MEPF BIM MODELING

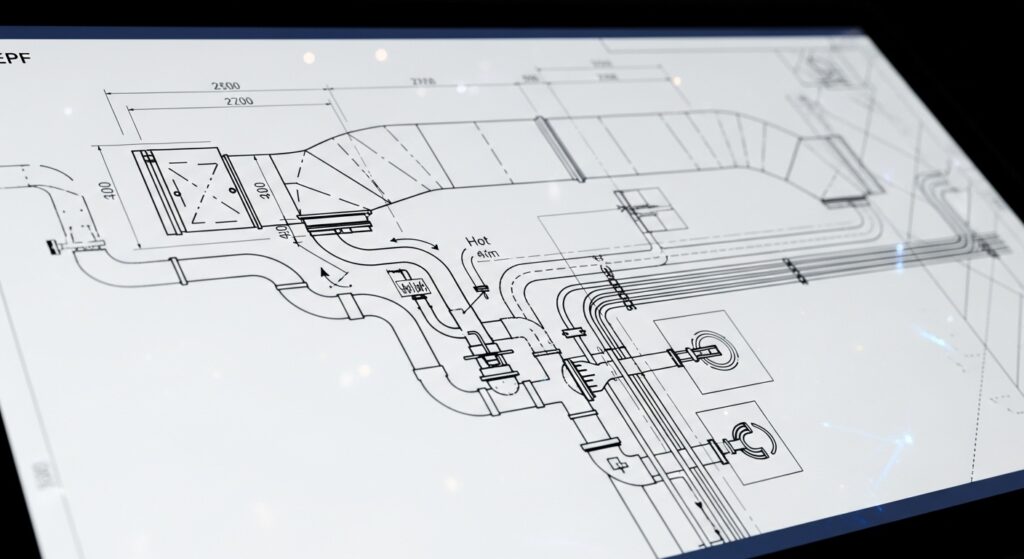

MEPF (Mechanical, Electrical, Plumbing & Fire Protection) BIM Modeling focuses on creating coordinated, clash-free, and intelligent 3D models of building systems. These models help optimize design, enhance collaboration, and improve construction efficiency.

Our services support MEP engineers, contractors, and project managers in improving project efficiency, reducing errors, and optimizing systems for cost-effective construction and long-term operational performance.

Our MEPF BIM Modeling Workflow:

Requirement Analysis & Project Setup

- Collaborate with MEP engineers, architects, and contractors to define project goals, modeling requirements, and deliverables.

- Develop project-specific templates for mechanical, electrical, plumbing, and fire protection systems, ensuring consistency in the modeling process.

- Define LOD (Level of Development) specifications based on project needs (e.g., LOD 300 for design development, LOD 350 for construction).

- Align the MEPF modeling scope with building codes, client specifications, and project timelines.

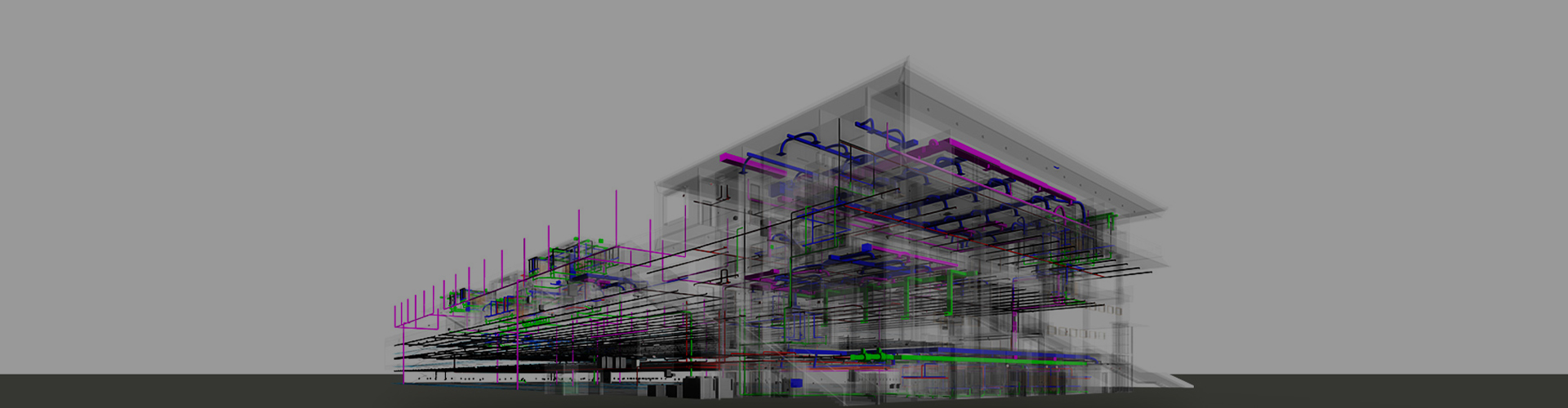

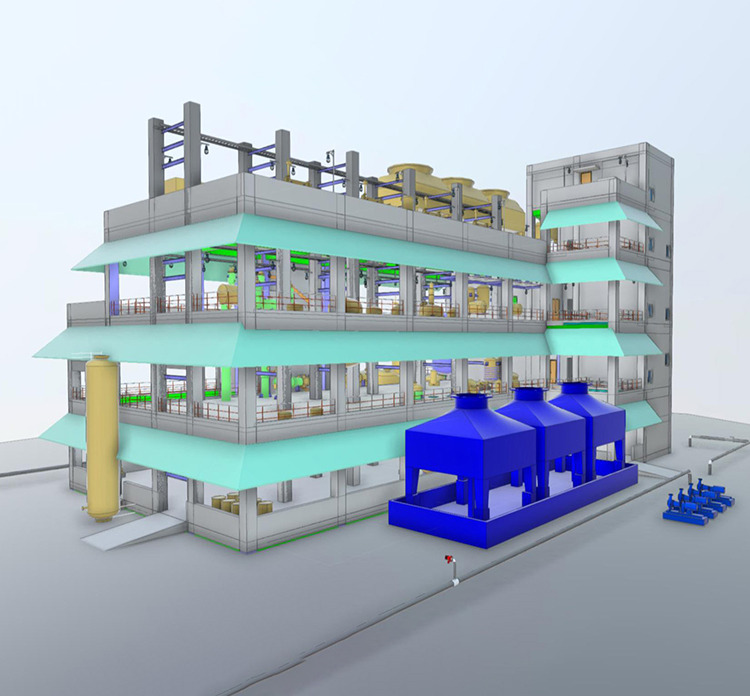

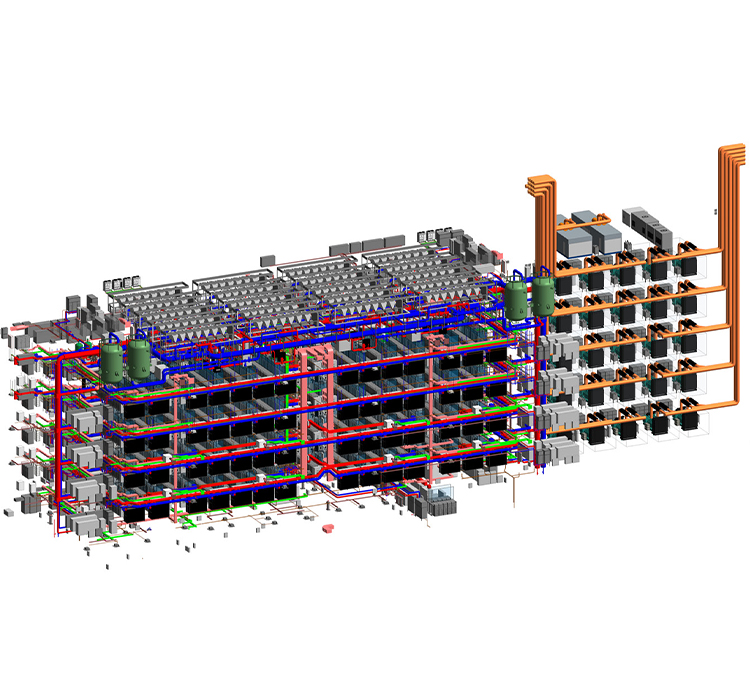

MEPF Model Creation

- Use Revit to create 3D models of all MEPF systems, including HVAC, lighting, plumbing, fire protection, and electrical distribution.

- Model ducting, piping, cabling, free sprinklers, and lighting fixtures with accurate dimensions and material properties.

- Include mechanical equipment, electrical panels, fire alarm systems, and plumbing fixtures as part of the coordinated MEPF model.

- Ensure system performance by incorporating fluid dynamics, airflow rates, and electrical load calculations into the model.

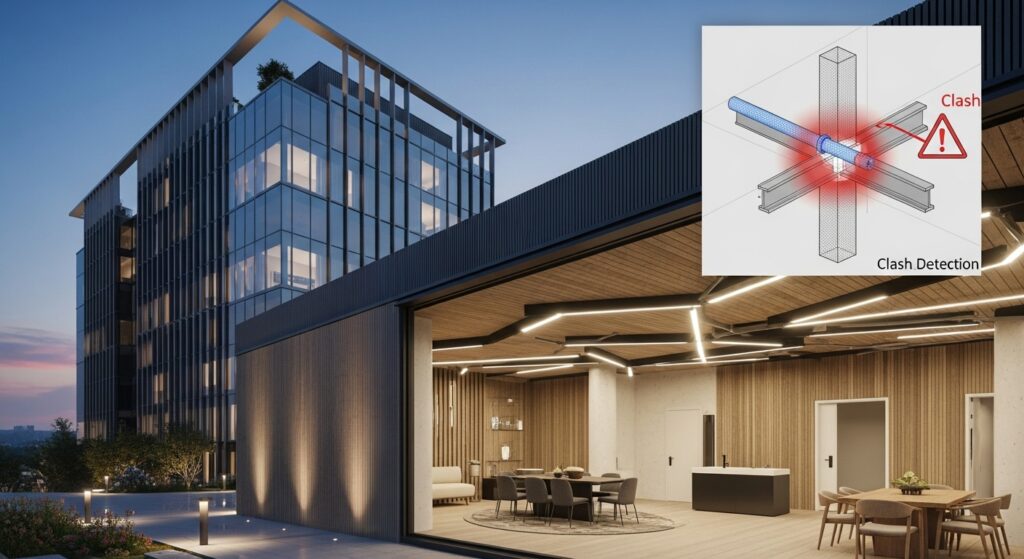

Coordination & Clash Detection

- Perform clash detection and coordination with architectural and structural models using tools such as Navisworks, BIM 360, or Revit’s collaboration features.

- Revit with Enscape for real-time rendering.

- Lumion and TwinMotion for photorealistic exterior and interior views.

- V-Ray for Revit for high-quality architectural visualization.

- Identify and resolve interdisciplinary conflicts, such as ducts crossing beams, piping in conflict with walls, or electrical systems blocking access to mechanical rooms.

- Create clash detection reports and collaborate with the project team to resolve issues early in the design process, avoiding costly rework during construction.

Detailed Design & Documentation

- Develop detailed MEPF drawings, including HVAC layouts, electrical riser diagrams, plumbing systems, and fire protection details.

- Provide schedules for equipment, fixtures, and material takeoffs to support procurement and construction.

- Ensure detailed documentation for installation, including ducting sizes, pipe routes, electrical panel locations, and fire safety equipment, directly from the Revit model.

- Integrate MEPF load calculations, performance specifications, and system capacity data into the BIM model for accurate, real-time updates.

3D Visualization & Simulation

- Generate realistic 3D renderings of MEP systems for visualization, design validation, and presentation purposes.

- Revit with Enscape for real-time rendering.

- Lumion and TwinMotion for photorealistic exterior and interior views.

- V-Ray for Revit for high-quality architectural visualization.

- Use virtual walkthroughs and simulations to ensure that all systems are adequately integrated, accessible, and meet the client’s functional requirements.

- Conduct energy simulations and ventilation analysis within the Revit model to optimize system performance and improve energy efficiency.

Get in Touch with a Member of Our Team Today