BIM Quantity Take-off

We offer automated quantity takeoff services by extracting data directly from BIM models, ensuring precision and reliability in material and cost estimation. By leveraging tools such as Revit, Navisworks Quantification, ACC Takeoff and CostX, we deliver detailed quantity reports tailored to specific project needs. These reports cover all essential construction materials and quantities required for procurement and budgeting.

Our BIM Quantity Takeoff service eliminates manual errors and improves efficiency in cost estimation and resource planning. We assist clients by aligning quantity data with construction timelines and ensuring accurate input for tendering processes. This enables better financial planning and efficient use of resources.

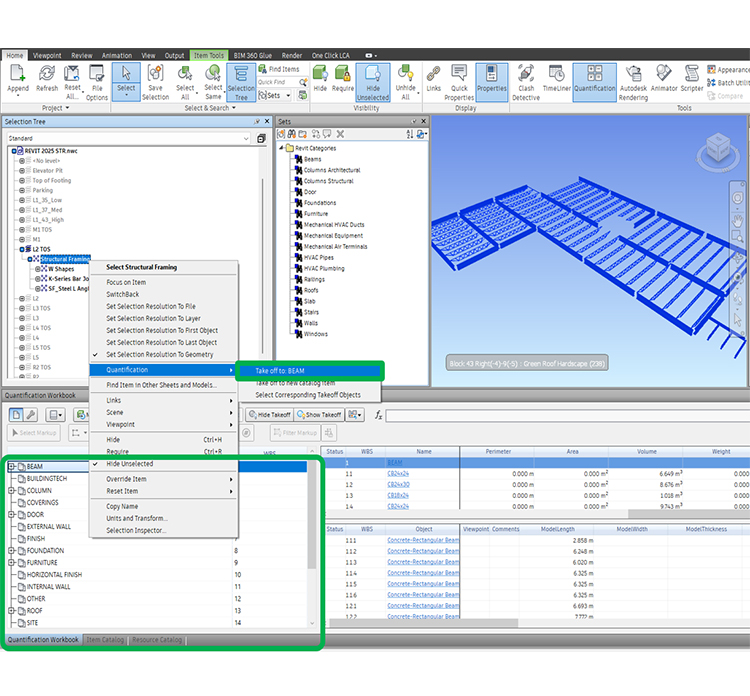

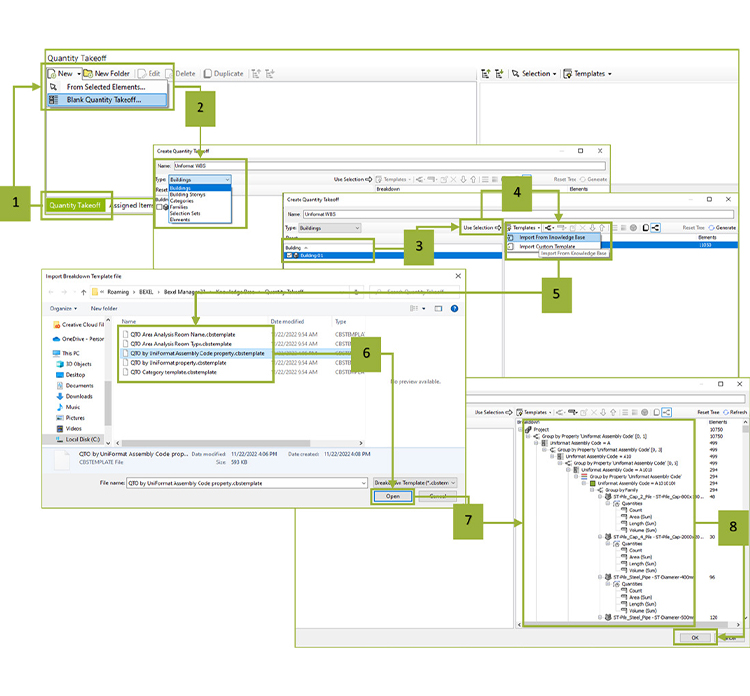

Automated Quantity Extraction

Using BIM models created in software like Autodesk Revit, we automatically extract quantities of materials, components, and systems from the model. This eliminates manual measurements and ensures that all quantities are accurate, up-to-date, and aligned with the design.

Real-Time Data for Cost Estimation

Our BIM Quantity Takeoff services enable real-time updates to quantities as the design evolves. This allows for continuous cost estimation and budgeting throughout the project lifecycle, ensuring that clients have accurate cost data at every stage of design and construction.

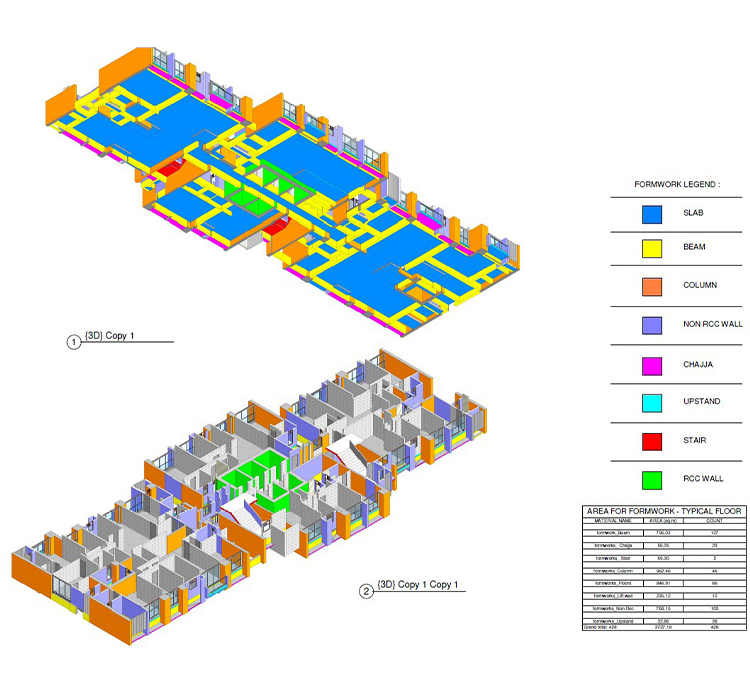

Detailed Material and Component Breakdown

We provide comprehensive breakdowns of materials and components, including detailed specifications, dimensions, and quantities for various building elements (e.g., walls, floors, doors, windows, MEP systems). This granular level of detail ensures that all required materials are accounted for and can be easily ordered or procured.

Enhanced Accuracy and Efficiency

Our BIM Quantity Takeoff service eliminates the errors and inefficiencies of manual takeoffs. The BIM model serves as a single source of truth, ensuring that quantities are consistent and accurate, minimizing discrepancies between the design and the final built structure.

Cost Planning and Budgeting

With accurate quantities at hand, we assist in the preparation of cost estimates, project budgets, and material schedules. This ensures that projects are planned effectively and within budget, avoiding cost overruns and facilitating better financial management.

Integration with Procurement and Scheduling

The quantities extracted from the BIM model can be seamlessly integrated with procurement systems, helping streamline the ordering and delivery of materials. Additionally, the data can be used for creating accurate schedules, ensuring materials are available when needed to avoid delays.

BOM (Bill of Materials) Generation

We generate detailed Bills of Materials (BOM) from the BIM model, providing a complete list of all materials required for the project, along with relevant specifications and quantities. This serves as a critical document for procurement teams, contractors, and project managers.

Benefits

- Reduces manual errors and enhances accuracy in estimation.

- Saves time by automating quantity extraction from BIM models.

- Improves procurement planning with detailed and reliable reports.

- Supports tendering and bidding processes with accurate data.

- Ensures transparency in material planning and usage.

- Facilitates resource optimization and cost control.

- Increases confidence in meeting project budgets.